|

KLIPPEL ANALYZER SYSTEM Linear Parameter Measurement (LPM) Using Fixed Mmd Method |

|

|

|

Driver

Name: |

SS 9 |

|

Driver

Comment: |

|

|

Measurement: |

LPM

subwoofer Fixed Mmd |

|

Measurement

Comment: |

|

|

Date: |

07/21/07 |

|

Time: |

19:37:16 |

Comments

Measured BL was lower than included

datasheet. Data gives 11.67 measured value is 10.37. Note that Klipple measurement does correlate with the Scan-Speak

frequency response sensitivity of 80.2 @2.83 volts.

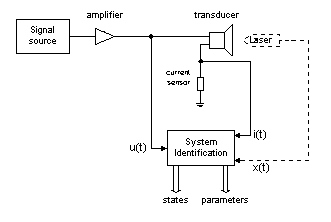

MEASUREMENT TECHNIQUE

A paper detailing the

measurement methods used can be found at: Fast

and Accurate Linear Parameter Measurement

Testing on the woofer was

performed using the Fixed Mmd method. This yields by

far the most accurate results for compliance values. The measurement module

identifies the electrical and mechanical parameters (Thiele-Small parameters)

of electro-dynamical transducers. The electrical parameters are determined by

measuring terminal voltage u(t) ![]() and current i(t) and

exploiting the electrical impedance Z(f)=U(f)/I(f). Furthermore the suspension

creep of the driver is identified giving more accuracy of the loudspeaker model

at low frequencies.

and current i(t) and

exploiting the electrical impedance Z(f)=U(f)/I(f). Furthermore the suspension

creep of the driver is identified giving more accuracy of the loudspeaker model

at low frequencies.

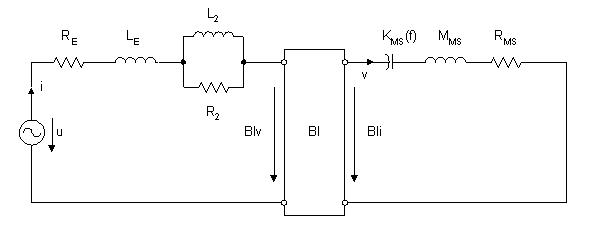

Measurement Results

Linear electrical

and mechanical parameters

The measurement module

determines the components (Thiele-Small Parameters) of the linear loudspeaker

model below describing the small signal behaviour of the driver.

The table

below shows the electrical and mechanical parameters of the linear driver

model, the derived parameters (resonance frequency, loss factors etc.) and the

parameter of the suspension creep factor.

|

|

|||

|

Name |

Value |

Unit |

Comment |

|

Electrical Parameters |

|

|

|

|

Re |

6.10 |

Ohm |

electrical voice coil resistance at DC |

|

Krm |

0.0711 |

|

WRIGHT inductance model |

|

Erm |

0.38 |

|

WRIGHT inductance model |

|

Kxm |

0.0134 |

|

WRIGHT inductance model |

|

Exm |

0.64 |

|

WRIGHT inductance model |

|

Cmes |

997 |

µF |

electrical capacitance representing moving mass |

|

Lces |

32.73 |

mH |

electrical inductance representing driver compliance |

|

Res |

62.25 |

Ohm |

resistance due to mechanical losses |

|

fs |

27.9 |

Hz |

driver resonance frequency |

|

|

|||

|

Mechanical Parameters |

|

|

|

|

(fixed Mmd) |

|

|

|

|

Mms |

107.289 |

g |

mechanical mass of driver diaphragm assembly including air load and voice coil |

|

Rms |

1.729 |

kg/s |

mechanical resistance of total-driver losses |

|

Cms |

0.304 |

mm/N |

mechanical compliance of driver suspension |

|

Kms |

3.29 |

N/mm |

mechanical stiffness of driver suspension |

|

Bl |

10.37 |

N/A |

force factor (Bl product) |

|

|

|||

|

Loss factors |

|

|

|

|

Qtp |

1.043 |

|

total Q-factor considering all losses |

|

Qms |

10.865 |

|

mechanical Q-factor of driver in free air considering Rms only |

|

Qes |

1.064 |

|

electrical Q-factor of driver in free air considering Re only |

|

Qts |

0.969 |

|

total Q-factor considering Re and Rms only |

|

|

|||

|

Vas |

23.1708 |

l |

equivalent air volume of suspension |

|

n0 |

0.045 |

% |

reference efficiency (2 pi-radiation using Re) |

|

Lm |

78.76 |

dB |

characteristic sound pressure level (SPL at 1m for 1W @ Re) |

|

Lnom |

79.94 |

dB |

nominal sensitivity (SPL at 1m for 1W @ Zn) |

|

|

|||

|

rmse Z |

7.02 |

% |

root-mean-square fitting error of driver impedance Z(f) |

|

|

|||

|

Series resistor |

0.00 |

Ohm |

resistance of series resistor |

|

Mmd (fixed) |

105.290 |

g |

Mmd value specified by the user |

|

Sd |

232.00 |

cm² |

diaphragm area |

Suspension creep factor

Some loudspeaker suspension

materials exhibit significant creep (continued slow displacement under

sustained force) in their dynamic behaviour. Therefore the traditional

low-frequency loudspeaker model is expanded to incorporate suspension creep by

replacing the simple linear compliance by the dynamic transfer function [1].

where CMS is the linear compliance and ![]() fs

is the driver resonance frequency. There is a straight forward interpretation

of the creep factor

fs

is the driver resonance frequency. There is a straight forward interpretation

of the creep factor ![]() . The quantity

. The quantity ![]() 100% indicates the decrease of the

compliance CMS(fs) in

percentages at low frequencies. For a frequency one decade below the resonance

frequency fs the compliance CMS(fs) is decreased by

100% indicates the decrease of the

compliance CMS(fs) in

percentages at low frequencies. For a frequency one decade below the resonance

frequency fs the compliance CMS(fs) is decreased by ![]() 100% .

100% .

[1]

Knudsen, M. H. and Jensen, J. G. Low-frequency loudspeaker models that

include suspension creep. J. Audio

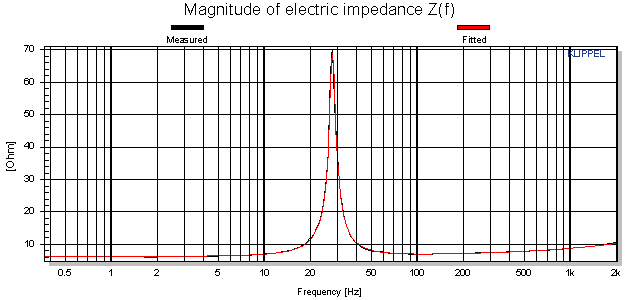

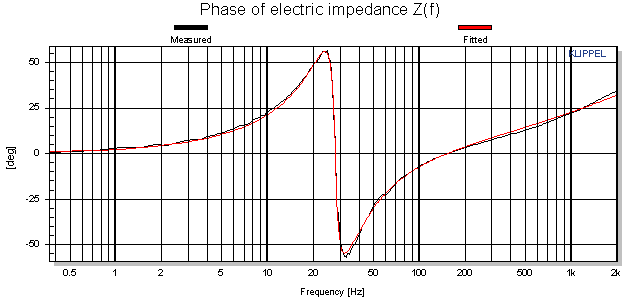

Electrical Impedance

The two figures below show

the magnitude and the phase response of the measured and estimated

transfer function Z(f)= U(f)/I(f) where

U is the terminal voltage and I is the current. The solid curve is the

ratio of the measured spectra U(f), I(f) while the thin curve is

the impedance of the linear driver equivalent circuit using the linear model

and the identified electrical parameters shown

Displacement Transfer

Function

The figure below shows the

magnitude of the measured and estimated transfer function Hx(f)= X(f)/U(f) between the voice coil displacement X and

the terminal

%20Magnitude.png)

Spectra of measurement signals

Voltage Spectrum

The diagram shows the

multi-tone spectrum of the voltage at the terminals. The blue lines represent the fundamental components

excited by the stimulus. The black noise floor lines represent the

residual measurement noise caused by the voltage sensor. If the grey noise + distortions exceeds the residual noise floor we see the distortions

generated by the nonlinearities of the power amplifier. This information is

important for assessing the distortion of the speaker in the current,

displacement and sound pressure below.

%20Spectrum.png)

Current Spectrum

The diagram below shows the

multi-tone spectrum of the current at the terminals. The red lines represent the fundamental components excited

by the stimulus. Note the notch of the spectrum at the resonance frequency of

the driver. The black noise floor lines indicate the residual noise

caused by the measurement system (current sensor). If the grey noise + distortions lines exceeds

the residual noise floor we see the distortions generated by the nonlinearities

of the speaker (assuming that the power amplifier is sufficiently linear).

%20Spectrum.png)

Displacement Spectrum

The diagram

below shows the multi-tone spectrum of the voice coil displacement measured

with the laser sensor. The violet lines represent the fundamental components excited by

the stimulus. Note the 12 dB/octave decay of the displacement spectra above the

resonance frequency of the laser. The black noise floor lines

indicate the measurement noise caused by the resolution of the used Laser

Sensor Head. Increasing the number of averaging will further reduce the

residual noise line. If the grey noise + distortions

exceeds the residual noise floor we see the distortions generated by the

nonlinearities of the speaker. These components are independent on the number

of averaging.

%20Spectrum.png)

Sound Pressure Spectrum

The diagram shows the multi-tone

spectrum of the sound pressure measured with the microphone. The green lines represent the fundamental components

excited by the stimulus.The black noise floor lines indicate the ambient noise during the

measurement. The grey noise + distortions

are the nonlinear

distortion components generated by the speaker.

%20Spectrum.png)

Signal

Characteristics

The table below summarizes important

statistical characteristics (peak values, head rooms, SNR ratio, …) of the

state variables (voltage, current, displacement and sound pressure). This

information is helpful for assessing the working point of the driver (Small -

Large Signal Domain) and to detect any malfunction operation (microphone or

laser not connected).

|

|

|||

|

Name |

Value |

Unit |

Comment |

|

HINT : |

|

|

Reduce Fmax to 20* fs to improve impedance fitting |

|

|

|||

|

U pp |

2.37 |

V |

peak to peak value of voltage at terminals |

|

U ac |

0.30 |

V rms |

AC part of voltage signal |

|

U dc |

-0.00 |

V |

|

|

U head |

47.2 |

dB |

digital headroom of voltage signal |

|

U SNR+D |

44.1 |

dB |

ratio of signal to noise+distortion in voltage signal |

|

fu noise |

1.1 |

Hz |

frequency of noise+distortion maximum in voltage signal |

|

|

|||

|

I pp |

0.28 |

A |

peak to peak value of current at terminals |

|

I ac |

0.04 |

A rms |

AC part of current signal |

|

I dc |

-0.00 |

A |

|

|

I head |

51.7 |

dB |

digital headroom of current signal |

|

I SNR+D |

21.4 |

dB |

ratio of signal to noise+distortion in current signal |

|

fi noise |

27.5 |

Hz |

frequency of noise+distortion maximum in current signal |

|

|

|||

|

X pp |

0.60 |

mm |

peak to peak value of displacement signal |

|

X ac |

0.09 |

mm rms |

AC part of displacement signal |

|

X dc |

0.02 |

mm |

|

|

X head |

50.2 |

dB |

digital headroom of displacement signal |

|

X SNR+D |

20.9 |

dB |

ratio of signal to noise+distortion in displacement signal |

|

fx cutoff |

77.3 |

Hz |

frequency of highest valid line in displacement signal |

|

|

|||

|

p pp |

0.02 |

mV |

peak to peak value of microphone signal |

|

p ac |

0.00 |

mV rms |

AC part of microphone signal |

|

p head |

111.0 |

dB |

digital headroom of microphone signal |

|

p sum level |

-11.4 |

dB |

sum level of microphone signal |

|

p mean level |

-49.4 |

dB |

mean level of microphone signal |

|

|

|||

|

f sample |

6000 |

Hz |

sample frequency |

|

N stim |

16384 |

number of samples |

stimulus length |